OUR SERVICES:

-

PRODUCE STANDARD KNIFE

DRAWING , QUANTITY AND MATERIAL IS NECESSARY FOR QUOTING

-

SPECIAL KNIFE DESIGN

GIVE ME YOUR IDEA AND WE WILL HAPPY TO WORK TOGETHER

-

FREE CONSULTATION SERVICES

CONTACT US ANYTIME EVEN THEN YOU HAVN'T ORDER YET

QUESTIONS

OUR ENGINEER WILL PROVIDE GOOD SOLUTION ,PLEASE PROVIDE DETAIL AS BELOW:

- WHAT IS THE HARDNESS FOR KNIVES THAT YOU ARE USING NOW?

- HOW IS KNIFE USING ? WHAT IS THE TEMPUTER WHEN USING ? ANY ACID OR ALKALINE WATER ?

WE USUALLY TO USE FIVE DIFFERENT KINDS OF MATERIAL FOR KNIFE : CARBON ,TOOL STEEL ,HIGH SPEED STEEL ,CARBIDE STEEL ,STAINLESS STEEL. WE WILL SUGGEST THE CORRECT ONE ACCORDING WHAT YOU USING FOR

TOUGHNESS AND HARDNESS COULD NOT GET TOGETHER .BETTER HARDNESS MUST HAVE LOWER TOUGHNESS .BUT WE CAN STILL DO SOME DIFFERENT ACCORDING TO MATERIAL CHARACTERISTICS IN HEAT TREATMENT PROCESS. OUR GOOD HEAT TREATMENT EQUIPMENT AND PROFESSIONAL ENGINEER COULD PROVIDE GOOD SOLUTION FOR YOU

COATING AND USING MATERIAL WITH MORE Ni & Ai WOULD BE AVOID RUST EASILY

NOMALLY,THE CHEMICAL STRUCTURE OF STELL WOULD BE CHAGED IF THEY ARE IN THE HIGH TEMPERATURE.WE SUGGEST TO CHOOSE STEEL WITH HIGH Mo , Mo COULD RESISTANT TO HIGH TEMPERAUTRES .

Quality Control

Our professional team, together with modern equipment, ensures strict quality control throughout the entire production process. We are committed not only to the quality of our products but also to comprehensive after-sales service. Below is an overview of our quality control process:

PROCESS CONTROL

All production processes are strictly carried out in accordance with standardized S.O.P.

FINAL QUALITY CONTROL

To ensure full compliance with customer requirements, all products undergo strict inspection prior to shipment.

FEEDBACK

We highly value all feedback and suggestions from our customers, and we are committed to continuously improving our processes.

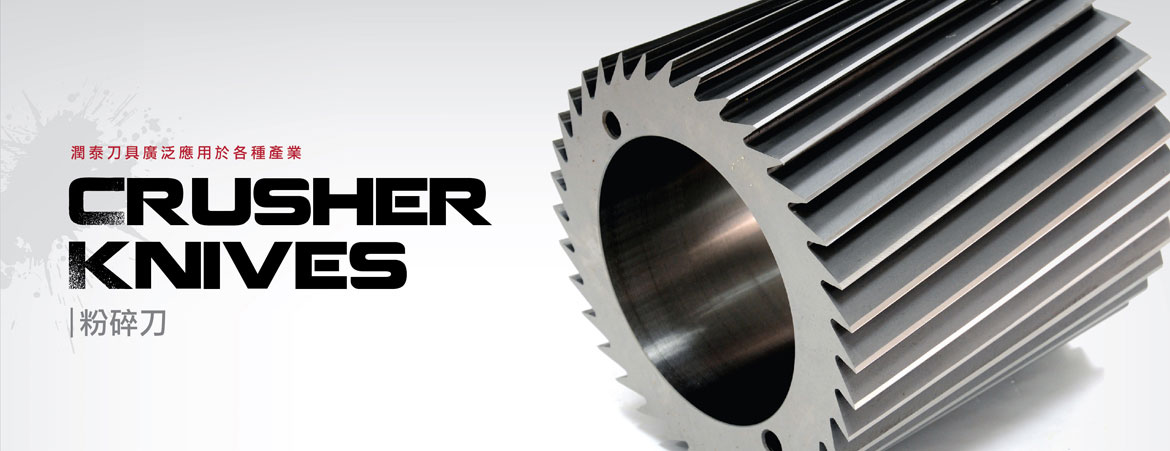

PRODUCT INFORMATION 產品資訊

SERRATED

齒刀

PAPER CUTTING

裁紙刀

CIRCULAR

圓刀